The automotive industry has witnessed significant advancements in windshield technology for enhanced safety. Initial laminated glass improved impact resistance, and further innovations incorporated structural components, airbag compatibility, and specialized tools for efficient replacement. Safety glass, reducing injury risks by preventing sharp shards, has driven regulatory changes mandating its use in modern vehicles. Windshield replacement, once a repair process, is now integral to vehicle safety systems, with auto body shops adopting strict protocols and advanced techniques to maintain structural integrity.

The evolution of windshield technology has been a driving force behind revolutionary changes in safety regulations, reshaping the automotive industry. As windshields transitioned from simple glass to advanced safety glass, incorporating laminates and impact-resistant materials, it became evident that this component played a critical role in passenger protection. This article delves into the transformative journey of windshield replacement, exploring its profound impact on safety standards before and after its implementation.

From enhancing structural integrity to mitigating risks associated with shattering glass, each advancement in windshield technology prompted regulatory bodies to establish stricter guidelines, ultimately fostering a new era of vehicle security and passenger protection.

- The Rise of Windshield Technology and its Impact

- – Exploring the evolution of windshield design and materials.

- – How advancements in safety glass influenced regulatory changes.

The Rise of Windshield Technology and its Impact

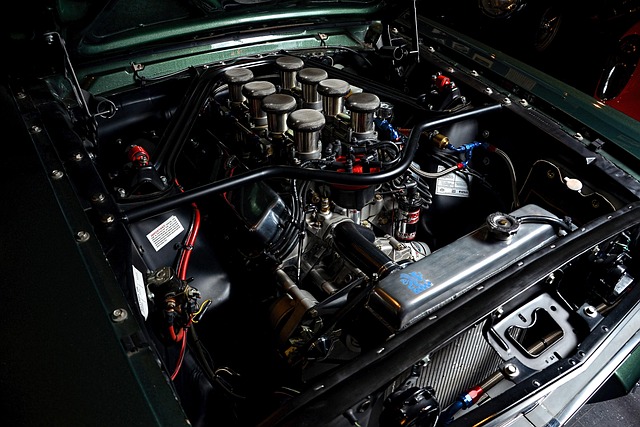

The evolution of windshield technology has been a game-changer in the automotive industry and has significantly influenced safety standards. Over time, windshields have transitioned from simple glass panels to sophisticated structures incorporating advanced materials and designs. This transformation began with the introduction of laminated glass, which offered improved impact resistance and crack suppression compared to traditional tempered glass. As auto manufacturers aimed to enhance overall vehicle security, the integration of safety features like impact-absorbing zones and airbag compatibility became a priority.

The need for efficient windshield replacement processes also played a pivotal role in shaping these regulations. Modern windshields are designed as integral parts of a vehicle’s structural framework, requiring specialized tools and techniques for safe removal and installation. Auto body shops now adhere to stringent protocols when conducting car body restoration, ensuring that replacements maintain the vehicle’s structural integrity and safety features. This focus on precision and quality has led to better overall vehicle performance and passenger protection in case of accidents.

– Exploring the evolution of windshield design and materials.

The evolution of windshield design and materials has been a pivotal aspect of automotive safety regulations. In the early days, windshields were primarily made of glass, offering minimal protection beyond what was provided by the vehicle’s frame. However, as technology advanced, so did the composition and design of these front-line defenses. Modern windshields incorporate advanced polycarbonate or laminated glass, which is not only more impact-resistant but also absorbs and disperses energy during collisions, significantly reducing the risk of injury to occupants.

This transformation in windshield construction has not only enhanced passenger safety but also influenced broader vehicle design. Auto repair services and vehicle repair services have had to adapt, incorporating specialized tools and techniques for effective windshield replacement while ensuring seamless integration with other components of the vehicle bodywork. This ongoing evolution underscores the dynamic interplay between technological advancements, safety standards, and the ever-changing landscape of auto repair.

– How advancements in safety glass influenced regulatory changes.

Advancements in safety glass have been a driving force behind regulatory changes in windshield replacement, significantly enhancing overall vehicle safety standards. Historically, windshields were made from traditional glass, which, while inexpensive, posed substantial risks upon shattering. The introduction of safety glass, featuring layers of polyvinyl butyral (PVB) interleaved with glass, has revolutionized windshield replacement. This innovative material not only prevents the glass from fracturing into sharp pieces but also holds the windshield in place during impact, significantly reducing the risk of injuries.

Regulatory bodies worldwide have recognized the potential of safety glass and implemented stricter guidelines for car restoration and collision repair services. These new standards mandate the use of safety glass in all modern vehicles, ensuring that fender repair processes incorporate this enhanced material to maintain optimal safety during accidents. As a result, windshield replacement has become more than just a repair procedure—it’s now a critical component of vehicle safety systems, reflecting a profound shift in how we approach automotive regulations.

Windshield replacement has undergone a remarkable transformation, driven by technological advancements that have forever changed safety regulations. As we’ve witnessed the evolution from simple glass to sophisticated safety glass, regulatory bodies have been compelled to adapt, ensuring that vehicles meet stringent safety standards. This ongoing process underscores the critical importance of staying at the forefront of windshield technology, not just for enhanced driver protection but also for maintaining compliance in the ever-evolving automotive landscape.